Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Review on a real time Green Enviro Solar Systems for On-grid and Off-grid Applications with AI and IoT Technologies

Authors: Dr. B Prakash Ayyappan, Mrs. R Yogeshwari, Mrs. EL. Thanga Uma, Mrs. G. Sugapriya, Mrs. K. Priyanka, Mrs. R. Meena, Ms. Jayapratha

DOI Link: https://doi.org/10.22214/ijraset.2024.63680

Certificate: View Certificate

Abstract

Solar photovoltaic (PV) plants must be constantly protected and supervised to keep them safe and reliable during their working lifetime. Incorporating smart technological equipment including artificial intelligence (AI) and internet of things (IoT) for remote sensing, fault det¬ection and diagnosing PV plants can help these plants achieve peak efficiency. Whi¬le renewable energy appears to be thriving globally, its intermittent nature creates a need to develop solutions for ensuring grid stability.The output of solar panels is influenced by a variety of environmental factors such as the amount of solar radiation, proportion of shadow, weather conditions and so on. Constantly monitoring these variables, particularly for off-grid and remote solar energy plants is a tedious task. A system may produce less electricity than its capacity because of the module being overly shaded, dirty and damaged among other factors. The smart PV monitoring system is a hybrid of hardware and software. It is an online platform that constantly monitors the solar system in real time using sensors, data loggers and other gadgets. In order to track and monitor the output of solar panels, the solar energy system is made of a number of sensors that are installed in various places. These sensors measure the irradiation, ambient temperature, module temperature, wind speed and other factors affecting the solar panel and its parts. The IoT gateway receives the generated data and uploads it to the cloud for monitoring. The collected data is then transmitted from the solar system’s inverter to the manufacturer’s monitoring database. With the help of IoT, the analysed data is transmitted to an application for predictive maintenance and investigation. The user and installer can quickly access the data that has been uploaded to the cloud at any time through the monitoring application. On the basis of past data patterns, comparative analysis can be done using real-time monitoring data. The main benefits the energy sector can gain from IoT are better energy efficiency, reduction of the environmental effect of energy usage, higher percentage of renewable energy, and much more.

Introduction

I. INTRODUCTION

Silicon, the most common resource on Earth after oxygen. Solar panels are made up of photovoltaic cells made from a semiconductor photosensitive material: pure silicon (Si). Silicon as a raw material to manufacture a solar panel.To extract silicon from silica, which is mainly found in the form of quartz, we use the carboreduction process (the extraction of metals at a very high temperature).

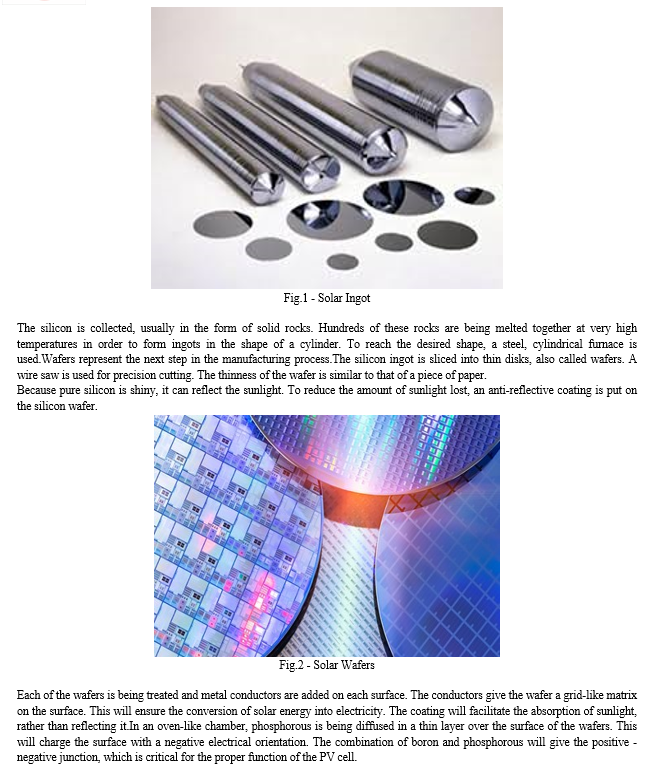

The raw materials are placed in an electric arc furnace (a type of electric furnace used in metallurgy) and submerged at high temperatures.These are necessary for certain chemical reactions to take place, including the reduction of silica (silicon oxide) and the removal of oxygen.The silicon obtained from this process is metallurgical grade, 98-99% pure. For photovoltaic and electronics, additional refining processes are then applied to improve the purity of the silicon. The latter eventually cools and solidifies into ingots, which are cut into plates.

Polysilicone cells are made from melting several silicon crystals together. You can recognise them by the shattered glass look given by the different silicon crystals. After the ingot has cooled down, grinding and polishing are being performed, leaving the ingot with flat sides.

III. MANUFACTURING PROCESS OF SOLAR PANEL

A. Silicon Rocks Melted to an Ingot

Silicon is the second-most abundant element – after oxygen – in the earth’s crust.To make use of silicon in the generation of solar energy, it first has to go through a purifying process. At this stage the silicon is in the form of sand or silicon dioxide, usually made from crushed quartz rock.After the silicon is purified it is then melted in a crucible to form an ingot. The ingot looks like a metal block at this point.

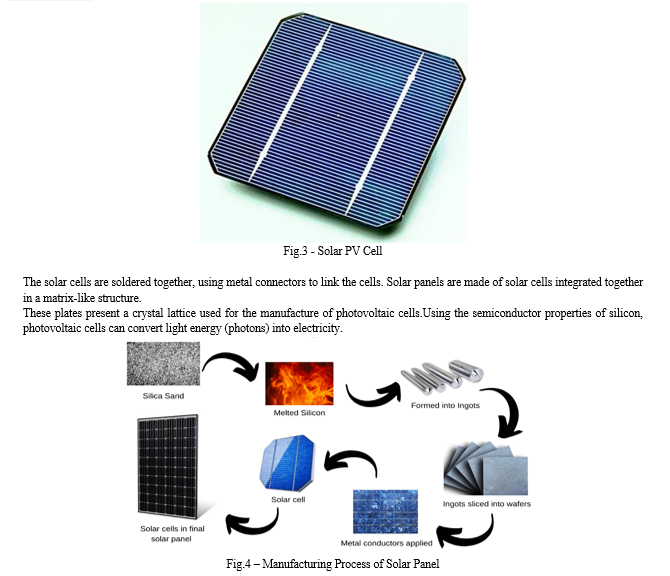

B. Ingots Sliced into Wafers

The ingots are sliced into blocks, using a silica carbide encrusted wire.Then with the same wire a different process is used to slice the silicon blocks into wafers. These wafers are about as thin as a piece of paper.The wafers are then cleaned doped with boron or phosphorus and tested repeatedly. As pure silicon is so shiny, it can reflect sunlight. The cell is needed to absorb the sun, not reflect, it is treated with an anti-reflecting coating.

C. Wafers Made into Solar Cells

After each wafer is treated metal conductors are added onto the surface. Giving the appearance of a grid-like matrix.These metal conductors convert the energy captured by the sun into electricity and you end up with a solar cell.

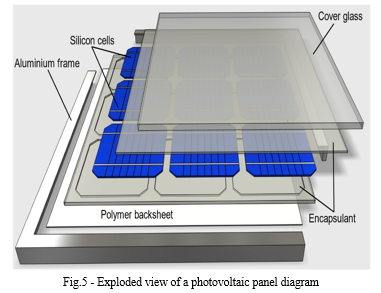

D. Cells Laminated to Glass

Solar cell lamination is a crucial step in the solar panel manufacturing process.After all, the solar panel needs to withstand all sorts of extreme weather conditions as it’s mounted on a roof.Improper lamination can lead to all sorts of issues and solar panel failure.The solar cells are encapsulated in a number of top and bottom layers. The top layer being that of tempered glass and the bottom a polymer-based back-sheet.

In-between the glass and the back sheet there is an encapsulant – EVA film.EVA stands for ‘ethylene vinyl acetate’ which is a specifically designed transparent polymer layer used to hold all the solar cells together when manufactured.This will also help ‘pad’ and protect the solar cells for such events as hail storms.

E. Glass Framed into a Solar Panel

Once all fitted and laminated together, the glass and solar cells are fitted into an aluminium frame.Aluminium is a great choice as it’s lightweight, won’t rust and durable. The aluminium frame is either anodised black or silver.The solar panel will also be fitted with a junction box and connectors. This is a small weatherproof box that holds all the cables and bypass diodes that protects and interconnects the panels.

F. Testing

Craig says the thing that stood out most was the amount of testing that is done throughout the entire process when making solar panels.From x-rays to micro-crack detection to the power class category and sorting.Also the continued improvement of the process’s that extracts as much power from each cell as possible.

G. Assembling the Solar Panel

The purpose of the module is to coat the cells to protect them and optimize their performance by limiting their heating.First of all, the cells are connected together in several strings to form a final matrix, often rectangular, composed of more or less 60 cells depending on the model of the panel. Each die is laminated on glass, i.e. reduced to thin sections. The cells are then framed (they are placed in a frame), then a junction box is added behind or under the panel to allow connections between the various modules of the installation and the inverter.

H. Testing the Modules

Once the module is ready, testing is carried out to ensure the cells perform as expected. STC (Standard Test Conditions) are used as a reference point. The panel is put in a flash tester at the manufacturing facility.

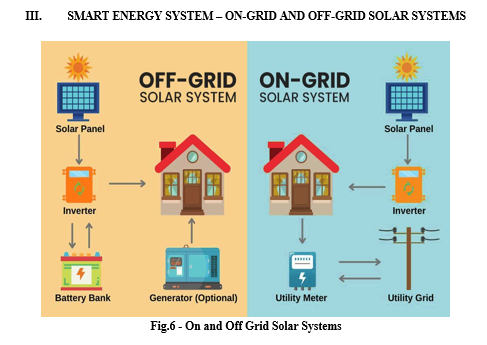

A. On-grid Solar Systems

On-grid solar power systems generate power using a solar power system and are directly connected to the utility power grid. These systems send excess power generated by the solar power system to the utility grid and consumers get compensated for the extra power fed back. These systems work in collaboration with the power grid. In the case when there is not enough sunlight to meet your business’ needs, the system runs on the power supplied by the grid. These systems are best suitable when your power consumption is high and you wish to reduce your electricity bills. On-grid systems can be installed with or without net metering. Being connected to the main grid, these systems do not work during power outages.One of the prior advantages of on-grid systems is their ability to provide a continuous power supply. When the sun is shining, the solar panels in Pakistan generate electricity, and any excess energy is returned to the grid.

On-grid systems generally have lower initial costs compared to their off-grid counterparts. They don’t need extensive battery storage systems to store excess energy for later use.On-grid solar systems are very cost-effective and easy to install.Businesses can recoup the cost of their investment by offsetting electricity bills in just 3-8 years. If a private, commercial or industrial building sets up a solar PV rooftop system it will be eligible to avail an ‘Accelerated Depreciation Benefit’ which is currently 80% in a year. At this rate, a business can completely depreciate the whole value of the project in approximately.

B. Off-grid Solar Systems

Off-grid systems work independently of the grid but have batteries which can store the solar power generated by the system. The system usually consists of solar panels, battery, charge controller, grid box, inverter, mounting structure and balance of systems. The panels store enough sunlight during the day and use the excess power generated in the night.The hallmark of off-grid systems is their ability to operate independently. This is especially useful in remote areas where grid connection might be impractical or costly. These systems empower users to generate and consume their electricity without relying on external sources.

Off-grid systems offer users greater control over their energy usage. With energy storage options like batteries, users can store excess energy generated during peak sunlight hours and use it at night or on cloudy days.Off-grid systems provide stability during power outages.

Since they are not dependent on the grid, users can continue to access electricity even when everyone else is in the dark.These self-sustainable systems can work independently and do not rely on the grid.They generate enough power that can be stored and used at night or when the power grid is down.These are ideal for remote areas where there is no power access from the grid.Grid failures and shutdowns will not affect your power supply.

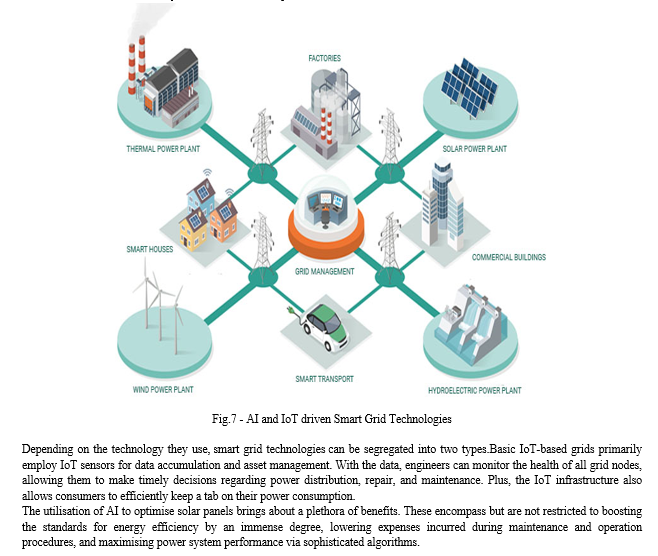

Smart grid technologies are electrical networks developed with the help of new technologies. Unlike traditional grids, smart grid technology incorporates elements like:

- Decentralized energy production

- Data sharing from consumers and grids

- Advanced tech like AI analytics, IoT sensors, Computer vision

Conclusion

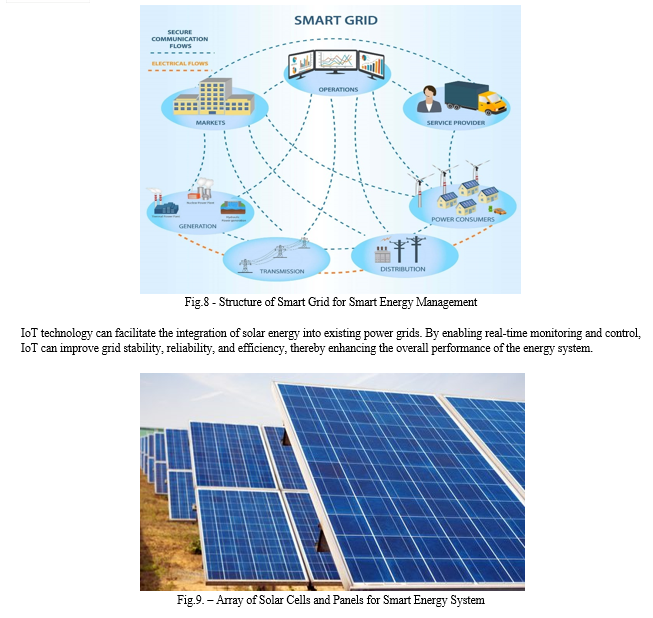

In conclusion, Smart Grids are a revolutionary change in the way electricity is produced, distributed, and consumed. By utilizing digital communication and automation, Smart Grids improve grid reliability, efficiency, and sustainability while giving consumers greater control over their energy usage. Smart Grid is an Electrical Grid with Automation, Communication and IT systems that can monitor power flows from points of generation to points of consumption and control the power flow or curtail the load to match generation in real time or near real time. A smart grid is an electricity network that uses digital and other advanced technologies to monitor and manage the transport of electricity from all generation sources to meet the varying electricity demands of end users. A modernized grid that enables bidirectional flows of energy and uses two-way communication and control capabilities that will lead to an array of new functionalities and applications. On-grid systems are typically more cost-effective and require less maintenance since they\'re connected to the utility grid, allowing you to sell excess power back to the grid. AI contributes to improving the efficiency of solar and wind power systems. AI algorithms can analyze weather patterns and historical data to predict the optimal times for energy production, allowing for better utilization of renewable resources. This system is designed to solve the problem occur in solar power generation like management problem, maintenance and to reduce the time of repair. Using this technology, the cost of solar energy (renewable energy) generation reduces. This also provides real time information to the user help to monitor the system.

References

[1] P. Pandiyan, S. Saravanan, R. Kannadasan, S. Krishnaveni, Mohammed H. Alsharif, Mun-Kyeom Kim, A comprehensive review of advancements in green IoT for smart grids: Paving the path to sustainability, Energy Reports, Volume 11, Pages 5504-5531, ISSN 2352-4847, 2024. https://doi.org/10.1016/j.egyr.2024.05.021. [2] Ansari, S.; Ayob, A.; Lipu, M.S.H.; Saad, M.H.M.; Hussain, A. A Review of Monitoring Technologies for Solar PV Systems Using Data Processing Modules and Transmission Protocols: Progress, Challenges and Prospects. Sustainability, 13, 8120, 2021. https://doi.org/10.3390/su13158120. [3] Chibuike Peter Ohanu, Salihu Ahmed Rufai, Ugbe Christiana Oluchi, [4] A comprehensive review of recent developments in smart grid through renewable energy resources integration, Heliyon, Volume 10, Issue 3, e25705, ISSN 2405-8440, 2024. https://doi.org/10.1016/j.heliyon.2024.e25705. [5] Siitonen, P., Honkapuro, S., Annala, S., & Wolff, A., Effects of trust and perceived benefits on consumer adoption of smart grid technologies: a mediation analysis. International Journal of Sustainable Energy, 43(1), 2024. https://doi.org/10.1080/14786451.2024.2350756. [6] Bari A, Jiang J, Saad W, Jaekel A. Challenges in the Smart Grid Applications: An Overview. International Journal of Distributed Sensor Networks; 10(2), 2014. doi:10.1155/2014/974682.

Copyright

Copyright © 2024 Dr. B Prakash Ayyappan, Mrs. R Yogeshwari, Mrs. EL. Thanga Uma, Mrs. G. Sugapriya, Mrs. K. Priyanka, Mrs. R. Meena, Ms. Jayapratha. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63680

Publish Date : 2024-07-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online